Recently, a research team led by Professor Shougang Chen from the College of Materials Science and Engineering at Ocean University of China (OUC) published a latest research article entitled “Template-Directed Growth of a 3D Hierarchical Structure of Well-Aligned Bimetallic MOF Arrays for High-Efficiency Electrocatalytic Air Sterilization” in the internationally authoritative journal Engineering. By employing a bioinspired strategy, the study reports a novel electrode material capable of achieving ultrafast and highly efficient inactivation of microorganisms in flowing air under low operating voltages, providing an innovative solution for air sterilization in enclosed spaces.

Indoor air quality is directly linked to public health. According to reports from the World Health Organization, air pollution levels in enclosed environments can be 5–10 times higher than those outdoors, contributing to approximately 4% of global diseases. However, existing technologies—such as ventilation, adsorption, and photocatalysis—often suffer from limitations in efficiency, stability, or safety, making it difficult to meet the demand for rapid, energy-efficient, and effective removal of airborne pathogenic microorganisms.

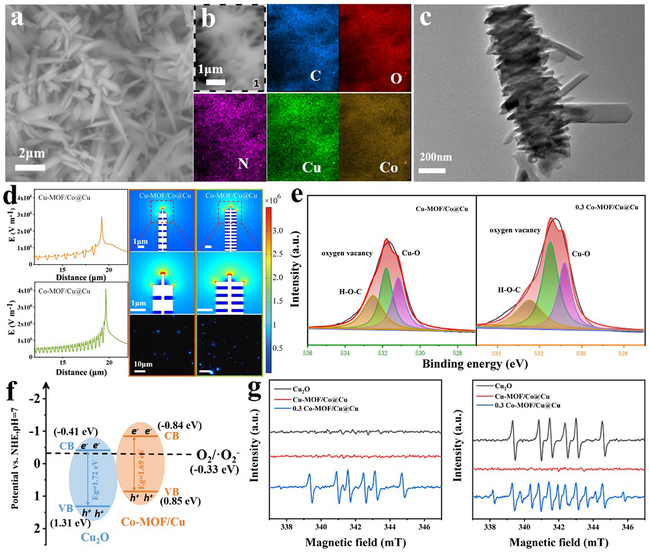

Fig. 1. (a-c) Preparation process and microscopic morphological characterization of Co-MOF/Cu@Cu electrodes with three-dimensional hierarchical structures; (d-g) materials, energy band structure analysis and reactive oxygen species synergistic sterilization mechanism

To address this challenge, the research team drew inspiration from natural structures and employed a template-directed growth strategy to fabricate well-aligned cobalt–copper bimetallic metal–organic framework (Co-MOF/Cu@Cu) arrays with a three-dimensional hierarchical architecture on copper substrates (Fig. 1). This unique structure endows the material with a large specific surface area, abundant active sites, and excellent structural stability. Experimental results show that when air flows through the electrode at a velocity of 1.5 m s⁻¹ under an applied alternating voltage of 12–24 V, a contact time as short as 0.003 s is sufficient to achieve bacterial inactivation efficiencies exceeding 99%, reaching 99.50% at 24 V. Through combined experimental and simulation analyses, the team systematically revealed that the exceptional sterilization performance arises from a synergistic mechanism of electroporation and reactive oxygen species (ROS) generation (Fig. 1). The sharp tips and edges of the hierarchical structure significantly enhance the local electric field, rapidly rupturing bacterial cell membranes via electroporation. Meanwhile, the applied electric field drives the electrocatalytic reduction of oxygen on the material surface, generating exogenous ROS, while simultaneously disturbing bacterial metabolism to induce endogenous ROS production—thereby achieving complete bacterial destruction through both physical and chemical pathways.

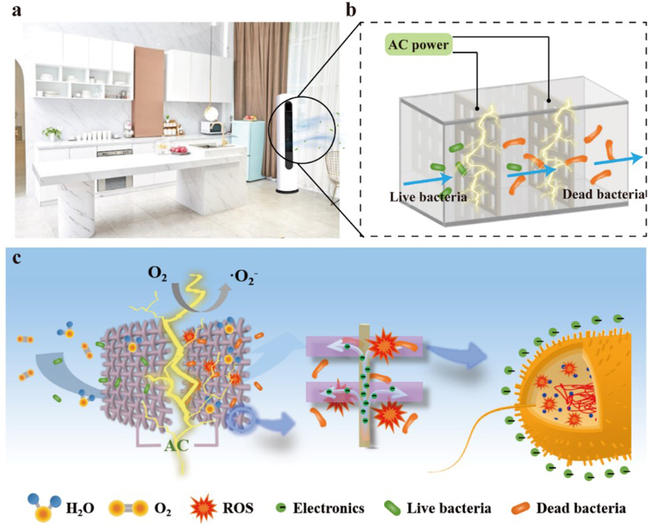

Figure 2. (a) Conceptual diagram of the application of the air sterilization system in an indoor environment, (b) Schematic diagram of the integration into the air conditioning pipe, and (c) Diagram of the sterilization mechanism of the MOF electrode filtration system

Notably, the electrode material can be directly integrated as a filtration module into existing air-conditioning and fresh-air ventilation systems (Fig. 2). Its modular design, low operating voltage, and instantaneous high-efficiency sterilization demonstrate strong energy-saving potential and engineering feasibility, offering a reliable technical route for real-time, online purification of large-volume airflow.

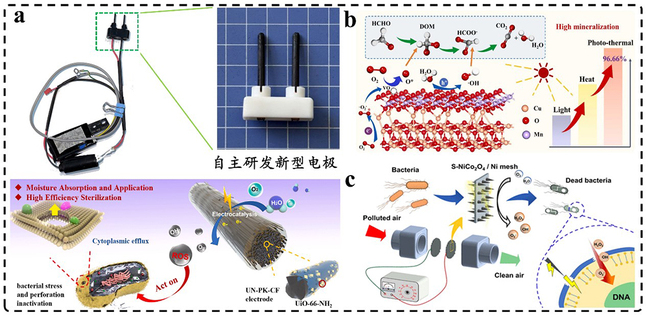

Figure 3. (a-c) Chen Shougang's research group has transformed its achievements and published papers in the field of indoor air pollution control in recent years

Group photo of the 2025 graduates of the research team (Professor Chen Shougang in the middle)

In recent years, guided by bioinspired design principles, the team has focused on regulating tip-discharge effects of conductive nanowire arrays, combined with photocatalytic and electrocatalytic degradation mechanisms, to achieve efficient removal of bacteria, viruses, and odor molecules in high-flow air or water environments. Through close collaboration with Hisense Home Appliances Group, the team has successfully developed antibacterial and deodorizing electrode materials and demonstrated their application in real-world scenarios, achieving significant breakthroughs in both purification performance and energy efficiency.

Liting Dong, a Ph.D. candidate (Class of 2022) in Marine Materials Science and Engineering at the College of Materials Science and Engineering, is the first author of the paper, and Professor Shougang Chen is the corresponding author. This work was supported by the General Program of the National Natural Science Foundation of China, the Key Project of the OUC President’s Fund, and commissioned projects from Hisense Home Appliances Group.

Text: Liting Dong

Article Link: https://www.sciencedirect.com/science/article/pii/S209580992500668X

Editor: Zhao Xiyun

Responsible Editor: Liu Li