Recently, Professor Huanlei Wang’s research group from the School of Materials Science and Engineering developed a novel hard carbon (HC) material with controllable graphitization and Ni single-atom modification, which was successfully applied as an anode for potassium-ion hybrid capacitors (PIHCs). The related findings were published in the top international journal Advanced Functional Materials (IF: 19.0) under the title “Joule Heating Driven Graphitization Regulation and Ni Single-Atom Modification in Hard Carbon for Low-Voltage and High-Rate Potassium-ion Storage.” Ocean University of China is the first-completing institution. Prof. Huanlei Wang and Assoc. Prof. Weiqian Tian are corresponding authors, and PhD student Lei Yang (Class of 2022) is the first author.

Potassium-ion Hybrid Capacitors and Challenges

PIHCs have emerged as promising energy storage devices due to their high energy density, high power density, and long cycle life. However, the large ionic radius of K⁺ (1.38 Å) results in sluggish kinetics and severe volume expansion, leading to poor rate performance and rapid capacity fading of anode materials. Among candidate materials, HC is considered highly promising owing to its low cost, wide availability, enlarged interlayer spacing, and abundant active sites. Typically, HC stores K⁺ through a combination of capacitive adsorption and diffusion-controlled intercalation processes. Unfortunately, the dominance of capacitive adsorption caused by amorphous structures and high defect density often leads to low low-voltage (≤1 V) charge capacity, limiting energy density. Moreover, these structural drawbacks reduce electrical conductivity and intensify side reactions, causing poor rate capability and low initial coulombic efficiency (ICE). Therefore, designing HC anodes with high ICE, large low-voltage capacity, and fast K⁺ storage capability remains both crucial and challenging.

Design Strategy and Research Findings

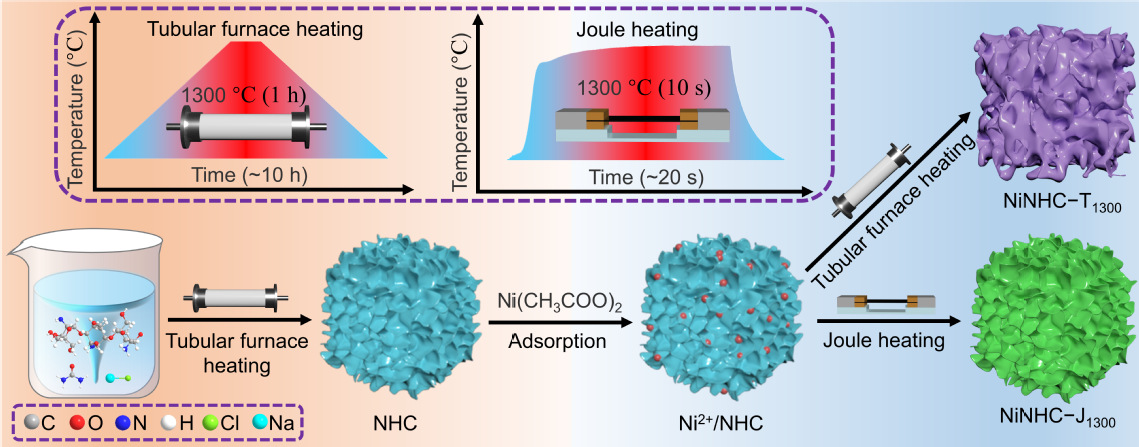

To address these challenges, the Wang group developed a Joule-heating-coupled metal salt catalytic strategy to produce HC materials with tailored graphitization and Ni–N₄ single-atom doping. Metal salts acted simultaneously as dopant precursors and graphitization catalysts, while optimized Joule heating conditions regulated graphitization degree, thereby improving ICE, low-voltage capacity, and rate performance.

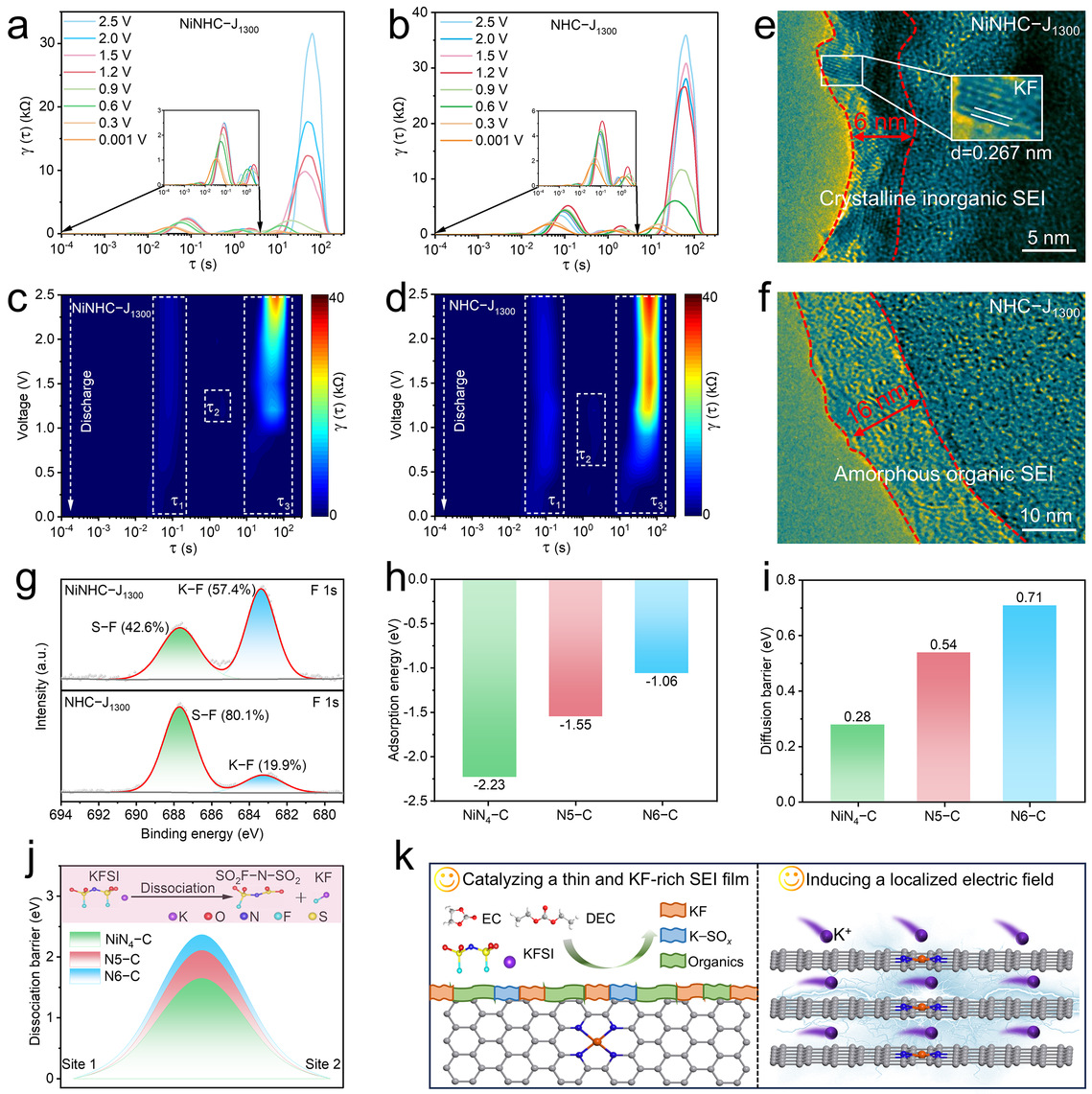

This method increased the Ni single-atom content to 2.29 wt.%. The Ni dopants promoted the formation of an ultrathin, KF-rich solid electrolyte interphase (SEI), improving interfacial K⁺ storage kinetics and structural stability. In addition, Ni doping induced local electric fields, enhancing K⁺ capture and bulk diffusion dynamics. As a result, the optimized HC anode delivered a low-voltage capacity of 290 mAh g⁻¹ (0.1 A g⁻¹) and a high-rate capacity of 144 mAh g⁻¹ (10 A g⁻¹). The assembled PIHC exhibited a high energy-power density balance (122 Wh kg⁻¹ at 16,167 W kg⁻¹) and excellent cycling stability (83% capacity retention after 8,000 cycles).

This work was supported by the National Natural Science Foundation of China, the Shandong Provincial “Taishan Young Scholar” Program, and the Major Basic Research Project of the Shandong Provincial Natural Science Foundation.

Link to Original Article:

https://doi.org/10.1002/adfm.202516237

Written by Lei Yang