Recently, Associate Professor Liu Shuai’s research group at the School of Materials Science and Engineering has achieved serial progress in the research of anodes, solid-state electrolytes, and cathodes for high-performance lithium metal batteries. Related results—Mg-Li-Cu alloy anode for highly reversible lithium metal batteries, Vinylidene carbonate-derived ultra-stable artificial SEI for lithium metal anode with ultra-long life, Ti₃C₂Tₓ MXene enhanced PEO/SN-based solid electrolyte for high-performance Li metal battery, and Ti₃C₂Tₓ MXene enhanced high-performance LiFePO₄ cathode for all-solid-state lithium battery—have been published in top-tier materials science journals Journal of Magnesium and Alloys (IF=15.8), Chemical Engineering Journal (IF=13.4), and Journal of Materials Science & Technology (IF=11.2; two papers). Ocean University of China’s School of Materials Science and Engineering is the first corresponding affiliation.

Lithium-ion batteries have been widely used in portable electronics, new energy vehicles, and large-scale energy storage systems. However, further improvement in their energy density is limited by inherent constraints. Lithium metal, with its high theoretical specific capacity (3860 mAh·g⁻¹) and low electrode potential (−3.04 V vs. SHE), holds promise for significantly extending the range of electric vehicles and electronics. Nevertheless, multiscale failure issues (electrode volume expansion/contraction, interface reconstruction, dendrite penetration, etc.) severely reduce battery lifespan and hinder industrialization. To address these challenges, Associate Professor Liu Shuai’s group collaborated with Nankai University, Shandong University, and Qingdao University to enhance the cycling stability and safety of lithium metal batteries from multiple dimensions—anode, electrolyte, and cathode:

1. Stabilizing Li Metal Anodes via Mg-Li-Cu Alloy

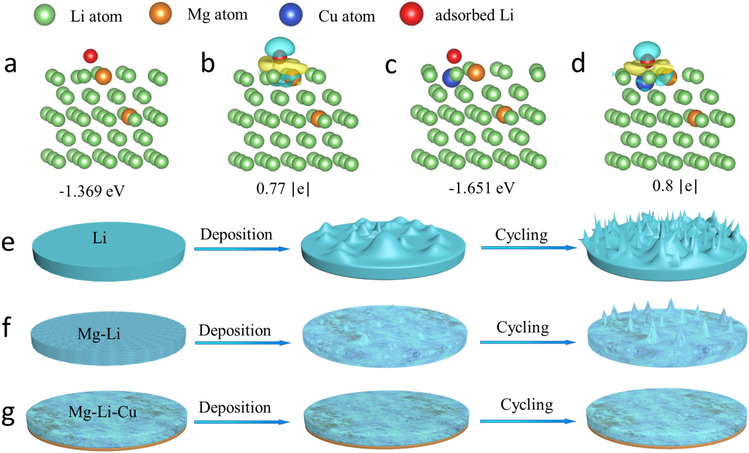

A lithiophilic Mg-Li-Cu alloy was designed to stabilize Li metal anodes: Lithium-magnesium alloy was first prepared by mechanical pressing, then heated to melt, allowing copper from the substrate to self-diffuse into the molten alloy. The Mg-Li-Cu alloy directly serves as the anode, enhancing cycling stability through high lithiophilicity and abundant nucleation sites that suppress Li dendrite growth. It avoids side reactions with electrolytes and provides high Li⁺ diffusion coefficients for excellent charge transfer kinetics. Notably, Mg-Li-Cu symmetric cells achieved a lifespan exceeding 9000 h at 1 mA·cm⁻²/1 mAh·cm⁻². Full cells paired with LiFePO₄ cathodes (LFP||Mg-Li-Cu) retained 96.4% capacity (148.2 mAh·g⁻¹) after 500 cycles at 1C. The first author of this paper is the postgraduate student Li Xinbin. (Journal of Magnesium and Alloys, DOI: https://doi.org/10.1016/j.jma.2024.05.024)

Fig. 1: Adsorption configuration, charge density difference, and deposition behavior of Li on Mg-Li-Cu alloy surface.

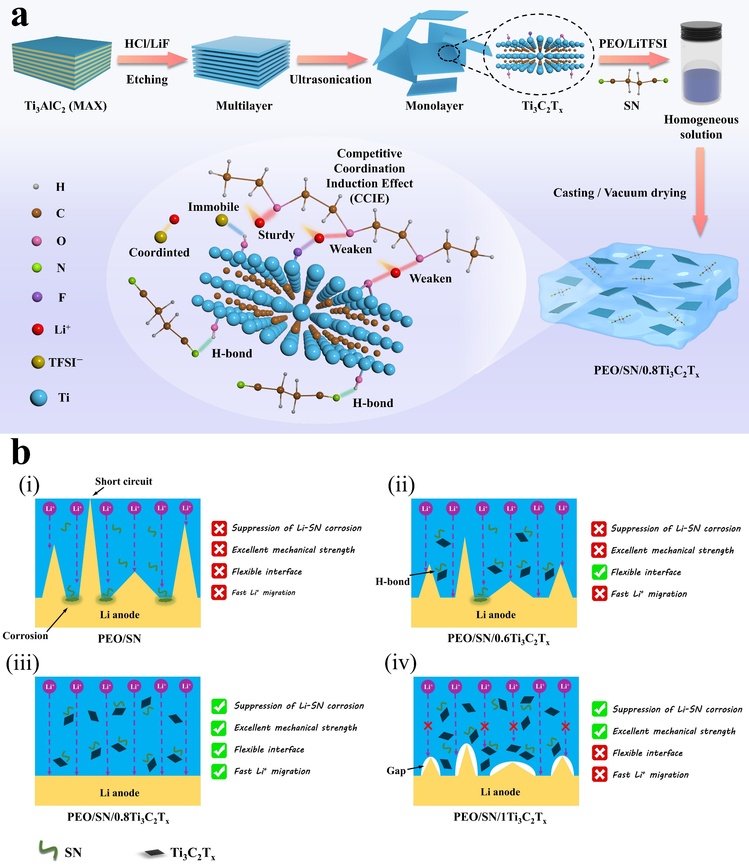

2. Ti₃C₂Tₓ-Reinforced Solid Polymer Electrolyte

A Ti₃C₂Tₓ-enhanced PEO/SN-based solid polymer electrolyte was designed with high ionic conductivity (2.17×10⁻³ S·cm⁻¹ at 35°C). Hydrogen bonds between Ti₃C₂Tₓ and free SN molecules inhibit corrosion of Li metal anodes. Competitive coordination weakens Li⁺ solvation, enabling efficient conduction. Optimized Ti₃C₂Tₓ content improves mechanical strength, suppressing dendrite growth. The assembled Li||Li symmetric cell stably cycled for >8000 h at 28°C. LiFePO₄||Li full cells exhibited 99.3% capacity retention after 300 cycles, delivering 151.7 mAh·g⁻¹. This work offers a scalable strategy for high-performance solid electrolytes. The first author of this paper is the postgraduate student Xu Hao. (Journal of Materials Science & Technology, 219 (2025) 101–112)

Fig. 2: Preparation process of the solid polymer electrolyte and reinforcement mechanism of Ti₃C₂Tₓ.

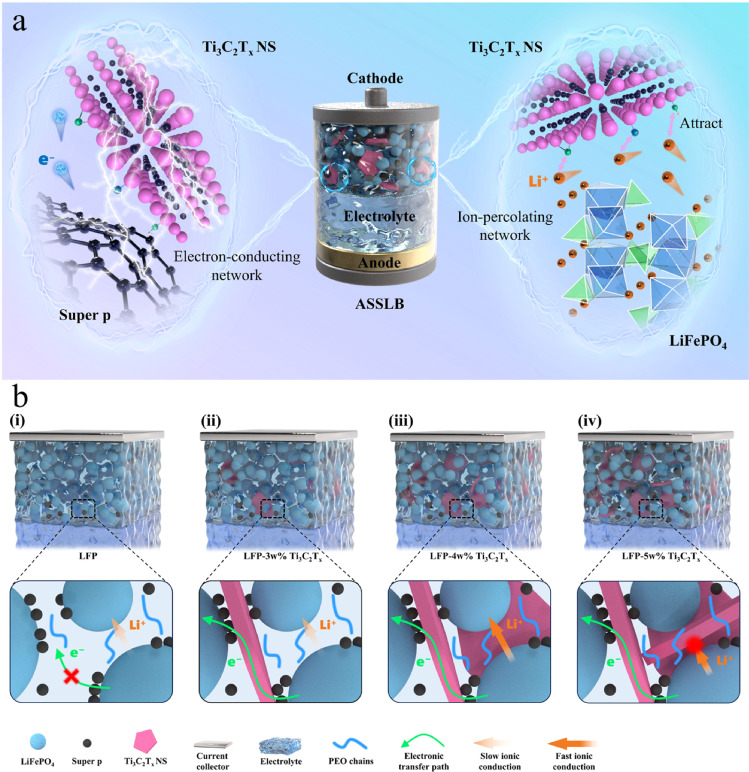

3. Ti₃C₂Tₓ-Modified Cathode for All-Solid-State Batteries

Ti₃C₂Tₓ MXene nanosheets (NSs) were introduced into LiFePO₄ cathodes to enhance rate capability and low-temperature performance. The highly conductive Ti₃C₂Tₓ NSs form continuous electron transport networks, while oxygen-containing functional groups weaken Li⁺ coordination in cathodes, building efficient ion percolation networks. The optimized cathode exhibited dual improvements in ionic/electronic conductivity. All-solid-state LiFePO₄||Li cells with PEO electrolyte delivered 91.5 mAh·g⁻¹ at 10C and retained 93.8% capacity (155.1 mAh·g⁻¹) after 1000 cycles at 1C. The battery also excelled under high loading, room temperature, and low-temperature conditions. The first author of this paper is the postgraduate student Xu Hao. (Journal of Materials Science & Technology, 223 (2025) 104–113.)

Fig. 3: Continuous electron conduction network and efficient ion percolation network constructed by Ti₃C₂Tₓ in the cathode.

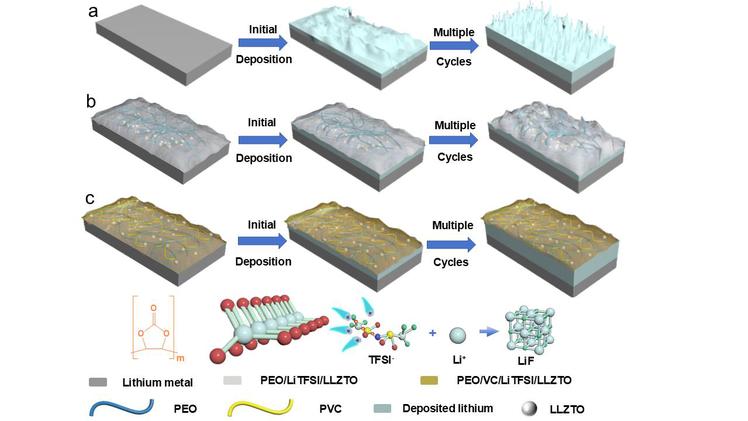

4. Ultra-Stable Artificial SEI Enabled by Vinylidene Carbonate

An artificial SEI with uniform Li⁺ transport and superior mechanical strength was developed to address uncontrolled Li deposition and irregular SEI formation. Vinylidene carbonate (VC) introduces strong polar groups into the SEI, alters electron transfer kinetics, and promotes LiTFSI decomposition, forming an LiF-rich SEI that enables fast Li⁺ transport and dendrite suppression. LLZTO additives enhance mechanical robustness. Li symmetric cells with this SEI stably cycled for >14,000 h at ultrahigh current density (25 mA·cm⁻²/25 mAh·cm⁻²)—the longest reported cycle life at such conditions. LFP||Li full cells maintained 99% capacity after 1,000 cycles at 0.5C and −2°C. The first author of this paper is the postgraduate student Ding Fan. (Chemical Engineering Journal, 518 (2025) 164411)

Fig. 4: Mechanism of VC-derived ultra-stable artificial SEI suppressing dendrites.

Research Profile of Associate Professor Liu Shuai

Specializing in novel amorphous materials for new energy and marine equipment, Liu Shuai joined the university in 2020 via the Young Talents Program Tier II. Supported by projects including the NSFC, Shandong Overseas Talent Program, and OUC Young Talents Fund, he has published 23 SCI papers (19 in top/authoritative journals) as corresponding author in Journal of Magnesium and Alloys (2025), Journal of Materials Science & Technology (2025×2), Chemical Engineering Journal (2025, 2023, 2021), etc. He received the 2022 Shandong Natural Science Second Prize, delivered 4 invited and 3 oral presentations at international conferences. In teaching, he leads 2 undergraduate education projects and 1 professional degree case library project, published 2 teaching papers, and was awarded OUC Outstanding Undergraduate Thesis Advisor.

Group Photo

Text/Photos: Zhang Chunyan