Recently, the research group of Professor Wu Jingyi from the College of Materials Science and Engineering at Ocean University of China has achieved new breakthroughs in the field of rechargeable seawater batteries. The related findings have been published in the internationally renowned academic journals Angewandte Chemie International Edition and Advanced Functional Materials.

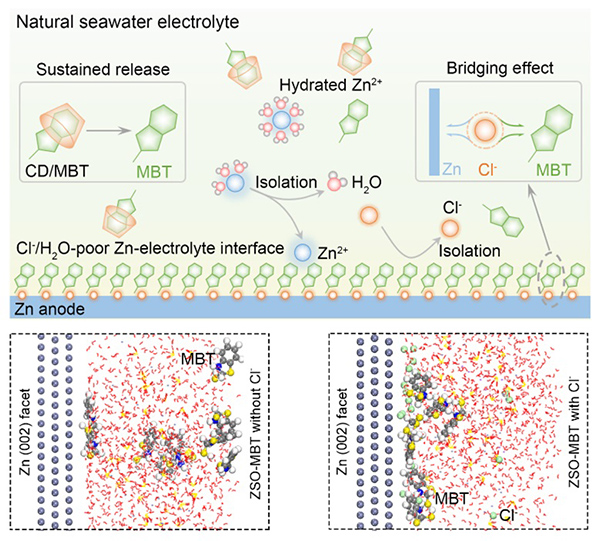

Seawater zinc-ion batteries can provide direct and safe energy supply for marine monitoring, deep-sea equipment, and coastal renewable energy storage, offering unique advantages for marine applications. However, the chloride-rich/water-rich anode-electrolyte interface in seawater batteries poses severe corrosion challenges to zinc metal anodes. To address this issue, the research team designed a seawater electrolyte containing a host-guest complex additive. This electrolyte uses 2-mercaptobenzothiazole (MBT) as the guest molecule, achieving controlled release via cyclodextrin (CD) as the host, effectively regulating its concentration in the electrolyte. Chloride ions form a dense MBT barrier at the electrode interface through a bridging effect, creating a chloride-deficient/water-deficient local microenvironment, significantly suppressing zinc anode corrosion and extending its cycle life. Experiments demonstrated that the zinc anode achieved stable cycling for over 400 hours at a practical depth of discharge (DOD) of 42.7%. A full cell with an N/P ratio of 1.92 retained 99% of its capacity after 600 cycles, and an ampere-hour-level pouch cell delivered an initial discharge capacity of 1.21 Ah with stable cycling over 50 cycles. This study provides new insights for developing low-cost, practical seawater zinc-ion batteries. The related paper, titled Chloride-Bridged Compact Interfacial Shielding for Practical Seawater Zinc Batteries, was published in Angewandte Chemie International Edition and selected as a Very Important Paper. The first author of the paper is Fan Wenjie, a 2022 doctoral student from the College of Materials Science and Engineering.

Figure 1. Schematic diagram of the corrosion inhibition mechanism and molecular dynamics simulation of the CD/MBT additive.

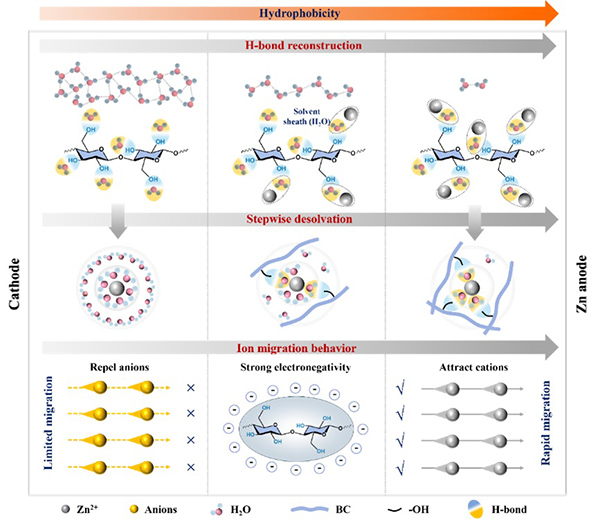

The research team also developed an ultrathin hydrophobic gradient cellulose separator with a thickness of only 18 μm. Leveraging the synergistic effects of its hydrophobic gradient structure and surface negative charges, this separator effectively blocks chloride ion penetration and reduces interfacial water activity. It not only constructs a stepwise desolvation path for hydrated zinc ions and promotes the formation of highly aggregated electrolytes to suppress side reactions but also repels chloride ions and homogenizes zinc deposition through electrostatic shielding, further enhancing the battery's cycling stability. The zinc anode using this separator achieved a long cycle life of 2,900 hours in natural seawater electrolyte and stable operation for 1,300 hours at 50% DOD. The assembled full cell exhibited a volumetric energy density of 233.1 Wh L⁻¹ (N/P = 2.3). This separator technology provides critical material support for marine energy storage systems. The related findings were published in Advanced Functional Materials under the title Hydrophobicity Gradient in Ultrathin Cellulose Separators for Durable Seawater-Based Zinc Batteries. The first author of the paper is Dong Yanying, a 2023 doctoral student from the College of Materials Science and Engineering.

Figure 2. Schematic diagram of the mechanism of the hydrophobic gradient separator.

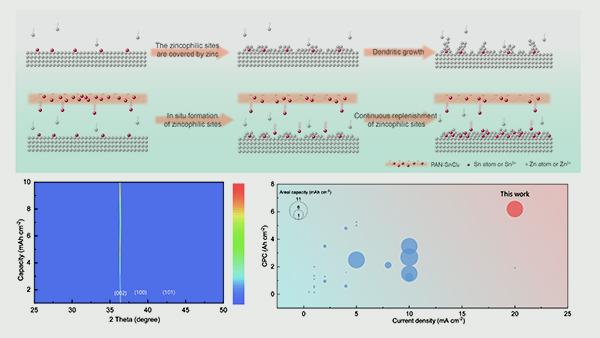

Additionally, the team proposed a dynamic interfacial alloying strategy to achieve adaptive interface regulation through controlled ion release. This strategy employs an electrospun composite interfacial film of stannous chloride and polyacrylonitrile, which gradually releases tin ions that are in situ reduced to metallic tin on the anode surface. Subsequent zinc deposition promotes the continuous formation of zinc-tin alloys, replenishing zincophilic sites and inducing epitaxial growth of the Zn(002) plane. This alloyed interface also accelerates the reduction of tin ions in local defect areas, guiding preferential zinc deposition and repairing structural integrity, thereby significantly enhancing the reversibility and stability of the anode. Batteries based on this strategy achieved an areal capacity of 3.5 mAh cm⁻² and stable cycling for over 1,000 cycles. The related research, titled Dynamic Interfacial Alloying for Highly Reversible Zinc Anodes, was published in Advanced Functional Materials. The first author of the paper is Wang Xingjie, a 2023 doctoral student from the College of Materials Science and Engineering.

Figure 3. Schematic diagram of the dynamic alloying process and comparison of electrochemical performance.

Group photo of the research team (Professor Wu Jingyi is in the center of the front row).

Ocean University of China is the first corresponding institution for the above papers, and Professor Wu Jingyi from the College of Materials Science and Engineering is the corresponding author. The research was supported by projects such as the Taishan Scholars Young Expert Program and the Ocean University of China Young Talents Startup Fund.

Text: Fan Wenjie

Article links:

https://onlinelibrary.wiley.com/doi/10.1002/anie.202515473

https://advanced.onlinelibrary.wiley.com/doi/10.1002/adfm.202513685

https://advanced.onlinelibrary.wiley.com/doi/10.1002/adfm.202516514