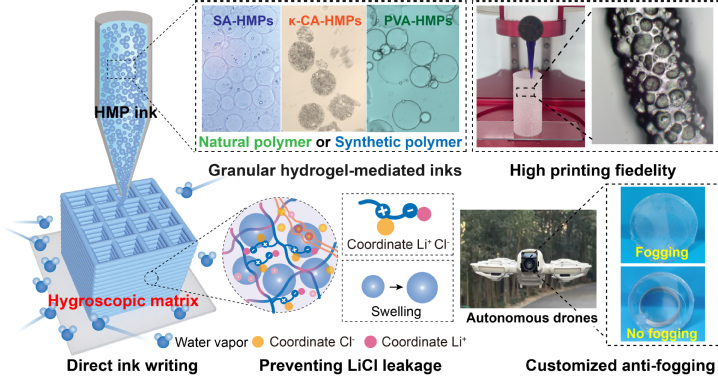

Recently, the research group of Professor Xu Xiaofeng from the College of Materials Science and Engineering published a research achievement titled 3D-Printed Hygroscopic Matrices Based on Granular Hydrogels for Atmospheric Water Adsorption and On-Demand Defogging in the top international materials journal Advanced Functional Materials. This work utilizes a granular hydrogel-based ink system to successfully construct hygroscopic 3D matrices with hierarchical structures through direct ink writing technology. The ink, composed of hygroscopic inorganic-organic components and an internally cross-linked network of granular hydrogels, was systematically optimized in terms of viscosity, rheological properties, and modulus, significantly enhancing printability, formational accuracy, self-supporting capability, and material applicability (Figure 1). By embedding LiCl within the stacked microgels, the material's moisture absorption capacity was effectively enhanced. Meanwhile, the osmotic network formed by zwitterionic copolymers not only strengthened the mechanical properties but also achieved high volumetric swelling, significantly improving structural integrity and reducing salt leakage. The printed hierarchical porous lattice structure greatly increased the specific surface area and mass transfer channels, thereby accelerating adsorption/desorption kinetics and maintaining excellent performance stability over cycles. As a core achievement of this research, the optimized hygroscopic matrix, compared to traditional hygroscopic aerogels, uses 53% less raw material, increases the specific surface area by 5.8 times, and significantly enhances the water absorption capacity by 1.4 times, reaching 2.85 g g⁻¹ within 48 hours at 90% relative humidity, positioning its performance among the leading levels reported so far for 3D printed hygroscopic materials.

Figure 1. Schematic diagram of the system based on granular hydrogel ink constructing a hygroscopic 3D matrix with hierarchical structures through direct ink writing technology, showcasing its customized anti-fogging application.

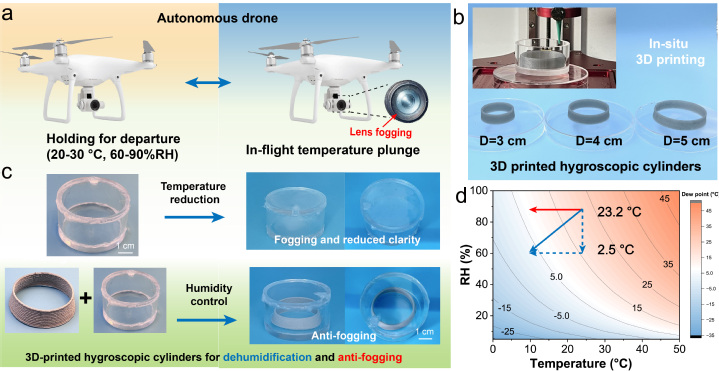

This microgel-mediated direct writing printing strategy not only broadens the applicability of 3D printing for hygroscopic materials but also enables the on-demand manufacturing of various customizable geometric shapes such as cubes and cylinders, allowing personalized design for specific dehumidification and anti-fogging applications. Through customized direct writing printing, a hygroscopic column structure integrable into drone lenses was successfully prepared (Figure 2). This structure can effectively control internal humidity, prevent lens fogging, and ensure lens light transmittance. This achievement demonstrates the capability of 3D printing technology in the customization of functional devices and provides material and process support for the design of next-generation drone optical systems, contributing to the development of the low-altitude economy. In the future, this hygroscopic structure can also be applied to other humidity-sensitive optical equipment, precision instruments, and vehicle-mounted sensor systems, helping to enhance the adaptability of equipment in complex environments.

Figure 2. (a) Schematic diagram of camera lens fogging on an autonomous drone in environments with abnormal temperature differences, (b) 3D printed hygroscopic cylindrical structures with different dimensions, (c) dehumidification test setup for real-time anti-fogging performance, and (d) distribution of dew point isotherms under different temperature and humidity conditions.

Wu Xiaochun, a 2022 doctoral student majoring in Marine Materials Science and Engineering at the college, is the first author of the paper. The research was supported by projects such as the National Natural Science Foundation of China, the Shandong Taishan Scholars Young Program, and the Shandong Natural Science Foundation. This study received support from domestic and international collaborating supervisors, including Professor Cui Hongzhi and Dr. Wang Zhihang.

Original article link: http://doi.org/10.1002/adfm.202514721

Text/Image: Wu Xiaochun